Resortecs x Decathlon: Industrialising Recyclable Swimwear

Resortecs has joined forces with Decathlon, the global leader in sports equipment and apparel, to develop a fully recyclable swimwear collection without compromising performance, functionality, or aesthetics. This collaboration blends state-of-the-art technology with high-performance design.

Acerina Trejo Machin, the Chief Technology Officer at Resortecs, explains, “We all know that a high percentage of elastane prohibits the recycling of fabrics, but eliminating elastane lowers the functionality and performance of a garment. To balance performance and recyclability, Decathlon developed Negombo, a fabric ensuring elasticity without the use of elastane.”

However, creating a swimwear garment with a recyclable fabric alone isn’t enough to meet the required performance and comfort, for which elastic bands are needed. Those elastic bands are not processable by recyclers and block the recycling of the swimwear. This is where Resortecs comes into play. Resortecs’ Smart Stitch™, combined with Smart Disassembly™, enables the efficient separation of the elastic bands from the main fabric at the end of the garment’s life cycle.

Acerina elaborates, “Resortecs’ active disassembly process ensures the maximum recyclability rate of the swimwear garment. Our technology allows for fully automatic disassembly, without any manual intervention, at a scale of up to 10 tons a day. This results in an impressive 63% increase in material recovery and is 10 times faster than conventional methods.”

The synergy between Resortecs and Decathlon allows for the creation of swimwear that is not only high-performing but also fully recyclable, without making any compromises in design, durability, or comfort.

Closing the loop has never been easier. By incorporating Resortecs’ disassembly solution, product designers can ensure circularity while focusing on their ultimate goal: creating garments that best fit their customer needs.

The Circular Economy has emerged as a pivotal economic model, offering not only sustainability but also significant financial opportunities. With projections indicating exponential growth, understanding its profitability is crucial for businesses and policymakers alike.

Current State and Forecast

The worldwide revenue of circular economy transactions was estimated to total roughly $339 billion in 20221. This is forecasted to more than double by 2026, reaching a $712 billion market opportunity. Keep in mind that this estimation only takes into account the categories of secondhand, rental, and refurbished goods, leaving aside a large pool of major circular business models, such as recycling. Including those in the equation would likely increase the value of the economy significantly, considering the projected value of the global waste recycling services market size of $88 billion, which in turn registers a 4.79% annual growth (CAGR) for the period 2020-20302.

In a forward-looking perspective, delving into the future reveals the potential of the Circular Economy to contribute an extra $4.5 trillion to global economic output by 2030, a figure that could surge to a remarkable $25 trillion by 20503. Additionally, the projections by The World Economic Forum highlight the transformative impact of recycling, reuse, and remanufacturing, suggesting that by 2025, these practices could unleash annual untapped resource savings of $1 trillion. Looking even further ahead, this value is predicted to double, reaching an impressive $2 trillion per year by 20504.

McKinsey’s Projections

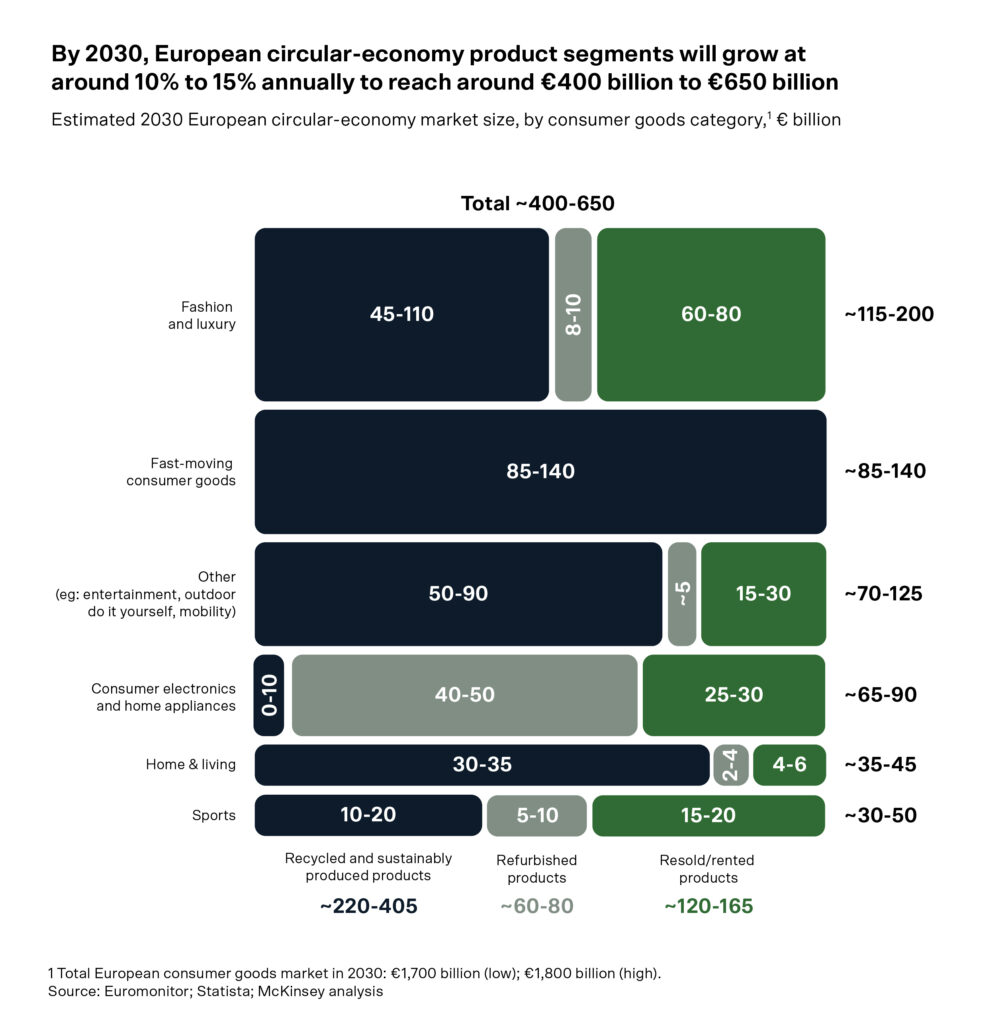

According to McKinsey’s projections, European consumer goods companies can achieve circular value pools exceeding €500 billion in annual revenues by 2030 through portfolio transformation, green business expansion, green premiums, and circular-focused operations. This significant shift will be propelled by changing consumer preferences, especially among younger generations who are using their purchasing power to express their values.

Zooming in on the added value per industry, McKinsey estimates that in FMCG, recycled and sustainably produced products are expected to see 15 to 25 percent annual growth (CAGR) until 2030, while recycling in fashion is expected to record 15 to 30 percent CAGR, generating €45 billion to €110 billion of annual value.

Part of the added value would be due to more efficient raw material usage. McKinsey reports that a circular economy would allow Europe, which is very resource-dependent, to grow resource productivity by up to 3% yearly. This transition is expected to generate a primary resource benefit of as much as €0.6 trillion annually by 2030 to the EU economy. Additionally, the forecast for non-resource and externality benefits is €1.2 trillion, bringing the annual total benefits to around €1.8 trillion.

This would translate into a GDP increase of as much as 7 percentage points relative to the current development scenario, with additional positive impacts on employment.

Drivers of Circular Economy

The reasons for the profitability of the Circular Economy are, among others, tax subsidies or preferential treatments from the government, a better competitive advantage, the reuse of waste into new products, and more efficient use of raw materials and energy consumption. Therefore, oftentimes, the benefits associated with circularity are greater than the involved costs5.

The profitability of the Circular Economy is multifaceted, encompassing tax incentives, competitive advantages, and resource efficiency. As benefits outweigh costs, embracing circularity presents not only sustainability but also financial gains for stakeholders.

Sources:

1 P. Smith, Worldwide circular economy revenue 2022-2026, https://www.statista.com/statistics/1337519/circular-economy-market-revenue/, November 2023.

2 Bruna Alves, Global waste recycling services market size 2022-2032, https://www.statista.com/statistics/239662/size-of-the-global-recycling-market/, January 2023.

3 P. Lacy, J. Rutqvist, Waste to wealth: The circular economy advantage, 2016.

4 Paul Ekins and Nick Hughes, Resource Efficiency: Potential and Economic Implications, https://www.resourcepanel.org/sites/default/files/documents/document/media/resource_efficiency_report_march_2017_web_res.pdf, March 2017.

5 Rubén Michael Rodríguez-González, Does circular economy affect financial performance? The mediating role of sustainable supply chain management in the automotive industry, March 2022.

©Filip Ysenbaert

De Tijd and its French-speaking counterpart L’Echo have proudly unveiled their esteemed selection of 30 Belgian companies leading the charge in combating climate change. Under the banner of “Changemakers,” this initiative celebrates organizations showcasing exemplary commitment and innovation in environmental stewardship. Among these distinguished nominees stands Resortecs, alongside other strong innovators like Purfi, Renewi, and Protealis.

The Changemakers initiative aims to spotlight companies that excel in leveraging technology, products, services, or business models to tackle climate change and protect the environment. Acknowledging the pressing need for collective action, De Tijd and L’Echo underscore the pivotal role of businesses in addressing this global challenge.

The nominated companies represent diverse sectors, including energy, software, construction, food, textiles, waste management, and recycling.

“Climate change stands as one of the most critical economic and societal challenges of our era,” states Isabel Albers, Editor-in-Chief of De Tijd and L’Echo. “We firmly believe that the innovative spirit and entrepreneurial drive of our companies are essential in tackling these challenges.”

Under the guidance of environmental economics professor Steven Van Passel from the University of Antwerp, a professional jury will select two standout companies – one startup and one established enterprise – as the ultimate Changemakers. Additionally, De Tijd and L’Echo subscribers will have the opportunity to cast their votes for their preferred Changemaker.

The distinguished jury panel includes industry luminaries and experts such as Julie Lietaer (European Spinning Group), Piet Colruyt (Impact House), Ignace Schops (Bond Beter Leefmilieu), Bertrand Piccard (Solar Impulse), Stéphanie Fellen (Smart2circle), François Gemenne (University of Liège), and Julien Pestiaux (Climact).

Voting for the Changemaker awards is now open to subscribers, with the winners set to be announced on March 12.

For more information about the Changemakers initiative and to cast your vote, visit Changemakers.be and tijd.be.

Join us.

Subscribe to our newsletter.

By subscribing, I agree with having my personal data stored and processed by Resortecs so I can receive future updates and marketing offers.