The Circular Economy Business Model: The New Standard of Doing Business

With the tightening European legislation on waste management and investment in the circular transition gaining traction, it becomes clear that circularity is no longer a buzzword, it’s a necessity for those who want to stay competitive. For the ones who don’t recognize the ongoing shift, this should serve as a wake-up call: Circularity is the new standard of doing business and first-movers are already reaping the benefits.

For the past years, the circular economy has already instigated transformative shifts across industries. In the fashion sector, for example, clothing resale is projected to surpass fast fashion by 2029, while the realm of plastics and consumer packaged goods is witnessing the metamorphosis of profit pools throughout the value chain, driven by mounting regulation, public expectations, and innovative recycling technologies1.

Governments are propelling this transformation, exemplified by the circular economy’s integral role in the European Green Deal, alongside circular economy roadmaps and regulatory measures established in nations like China, Chile, and France. As a result of this and other driving factors of circularity, the use of circular materials in the EU increased by roughly 41% between 2004 and 2021, accounting for 11.7% of total material use in 20212.

The Concept of a Circular Economy

According to McKinsey, approximately 63% of potential emissions reduction in the fashion industry is estimated to come from the use of cleaner energy sources3.

All of the other 37% of emissions reduction, however, necessitates innovative strategies: this is where circularity comes in. Processes encompassing prolonged product life cycles, shifts in consumer behaviors, adoption of circular business models, curbed overproduction, increased integration of recycled materials, and other circular economy principles could contribute immensely—up to 654 million metric tons of emissions reduction in the fashion industry by 2030, effectively bridging the emissions reduction gap. This approach can be similarly applied across various consumer goods industries3.

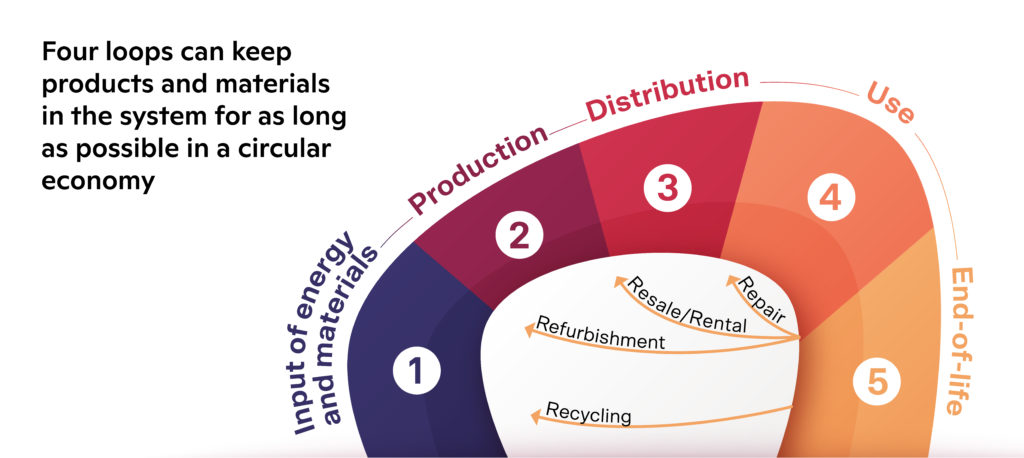

Within a circular economy framework, four pivotal loops support the extension of product life cycles: repair, resale/rental, refurbishment, and recycling.

Circularity is the Future Standard of Doing Business

It is clear that the circular economy is driving transformative changes across entire industries, opening up fresh prospects while also presenting risks for those who fail to keep pace. Embracing circular practices is becoming essential for businesses to thrive in this dynamic landscape.

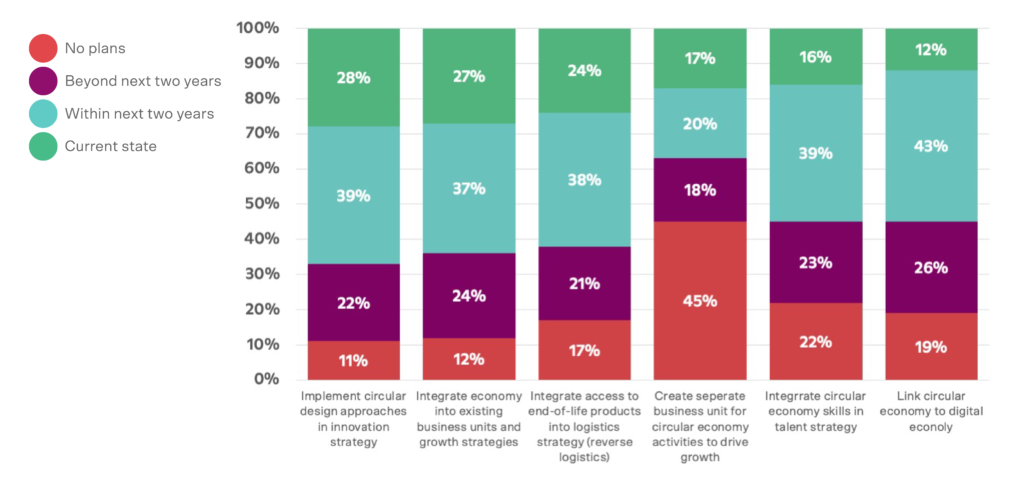

Already in 2019, roughly 28% of professionals in supply chain functions disclosed that they have incorporated circular design processes in their company innovation strategy. And around 39% stated that they plan on implementing circularity methods within the next 2 years4.

What Drives the Shift to Circularity?

Shifting consumer demand, regulation, technological progress, infrastructure, supply-side activity, and the macroeconomic environment are the main drivers of demand for circular consumer goods.

Shifting Consumer Demand

Research by McKinsey reveals that nearly 40% of European consumers consider sustainability to be of “high importance”. This heightened concern for sustainability is driving an increased demand for recycled, refurbished, and reused products. A recent survey conducted in 2021 indicates that approximately half of consumers in Germany, France, and the United Kingdom have already bought pre-owned items. As environmentally-conscious Generation Z individuals age, this trend is expected to gain further momentum3.

Regulation

Governments worldwide are progressively acknowledging the circular economy’s capacity to enhance competitiveness, foster robust supply chains, and achieve societal and environmental goals. Notably, the circular economy constitutes a fundamental element of the European Green Deal and features among the EU Taxonomy’s six environmental objectives. Several countries, including China, Chile, and France, have taken significant strides by implementing circular economy roadmaps and enacting legislation to promote sustainable practices. This growing recognition highlights the critical role of the circular economy in shaping future policies and fostering global sustainability5.

Other notable government initiatives are the Circular Economy Action Plan (CEAP) committing billions of euros to support initiatives that drive the journey towards achieving net-zero targets within the next decade. A central element of the CEAP involves a robust eco-design strategy, which emphasizes aspects like product longevity, reusability, upgrade potential, and advocating for a “right to repair.” Additionally, the plan emphasizes the integration of recycled materials, remanufacturing practices, and the promotion of high-quality recycling methods.

In the meantime, multiple European countries have begun the process of enacting extended producer responsibility measures. These initiatives offer substantial financial incentives to companies aiming to make the shift towards circular business models.

Technological Progress

Innovation progress in areas such as chemical recycling, digital product passports, and scalable disassembly technologies is allowing for the more and more accessible industrial-scale transition to circularity3.

The growing demand for solutions that facilitate product reselling, refurbishment, and recycling especially when it comes to developing scalable material collection and take-back programs, reverse logistics, as well as automated systems for material sorting, will drive further innovations in these areas, getting the industry a step closer to full circularity3.

Sources:

1 thredUP (GlobalData Market Sizing), ThredUP 2020 Resale Report,2020.

2 Bruna Alves, Circular material use rate in the European Union 2004-2021, https://www.statista.com/statistics/1316448/circular-material-use-rate-in-european-union/, June 2023.

3 Sebastian Gatzer, Stefan Helmcke, and Daniel Roos, Playing offense on circularity can net European consumer goods companies €500 billion, https://www.mckinsey.com/industries/consumer-packaged-goods/our-insights/playing-offense-on-circularity-can-net-european-consumer-goods-companies-500-billion-euros, June 2022.

4 Martin Placek, Supply chain approaches to the circular economy worldwide 2019, https://www.statista.com/statistics/1182874/circular-economy-supply-chain-approach/, April 2022.

5 Bocconi University, Ellen MacArthur Foundation, Intesa Sanpaolo (2021), The circular economy as a de-risking strategy and driver of superior risk-adjusted returns, http://www.ellenmacarthurfoundation.org/publications.

HNST Studio, the Antwerp-based label dedicated to creating jeans that embody transparency and circularity, partners with Belgian eco-design innovator Resortecs to launch new products made to be unmade—easy to disassemble for repair and recycling at the end of life.

The partnership debuts with the newly introduced Geri (for women) and Simon (for men) pants: crafted with up to 70% recycled cotton, these are HNST’s first jeans to feature an elastic waistband and drawstrings for unparalleled day-to-day comfort and flexibility.

Completely eco-designed for recycling, the jeans’ waistbands are stitched using Resortecs’ Smart Stitch™, an award-winning thread engineered to disappear under heat. This thread change at the design phase ensures that the jeans can be disassembled without manual intervention at the end of their lifecycle—allowing for their recyclable fabric to be automatically sorted out of the non-recyclable materials added to the waistband for more comfort.

“Our other jeans didn’t have elastic waistbands because they would be critical blockers for recycling. Collaborating with Resortecs allowed us to explore new possibilities to give our customers more comfort without compromising our non-negotiable commitment to circularity” stated Eva Engelen, Sustainability and Product Manager at HNST.

“We are two Belgian innovators trying to rewrite the future of fashion in a circular way,” said Cédric Vanhoeck, CEO at Resortecs. “This partnership with HNST showcases how our technology can unlock new possibilities for fashion players that want to design for recycling while keeping the creativity, functionality, and quality of their products”, he added.

The Simon and Geri pants are just the first drop of the HNST x Resortecs partnership. Both companies are committed to further integrating Resortecs’ design-for-disassembly solutions into other HNST designs, solidifying their shared vision of establishing circularity as the standard in the fashion industry. Consumers everywhere can now shop the collection at letsbehonest.eu and at select independent retailers in Europe, North America, and Japan.

Resortecs policy asks Waste Framework Directive revision

1. Swift introduction of mandatory and harmonised Extended Producer Responsibility (EPR) schemes for textile products across the EU to introduce their separate collection.

2. Extended Producer Responsibility fees should be eco-modulated to incentivise producers to ecodesign their products. Design for disassembly must be included as a criterion.

3. Include a 2030 target for textiles-textiles recycling target as well as a fibre-to-fibre sub-target (for when the former is no longer an option to avoid premature downcycling). These targets should increase over time.

4. To deliver the waste hierarchy principles in practice, recognition and support of so-called pre-recycling techniques that are preconditions to effective circularity operations, such as sorting and disassembly, should be developed and integrated into the modernised Waste Framework Directive.

____________________________________________________________________

Action to make circular economy the norm is urgent. The Circularity Gap Report 2023 demonstrates that the world’s circularity has declined from 9.1% to 7.2% over the past five years, whilst total material extraction has almost doubled since 2000, reaching 100 billion tonnes today. As recognised by the EU Green Deal, the Circular Economy Action Plan, the EU Industrial Strategy, and the Textiles Ecosystem Transition Pathway, the textiles sector is key to the green transition as it is the fourth most resource intense industry, it accounts for 10% of global greenhouse gas emissions, and less than 1% of all textiles waste collected enters into a circular loop.

Resortecs supports the European Commission’s 2030 vision for a competitive, resilient, and innovative textiles sector laid out in the EU Strategy for Sustainable and Circular Textiles, particularly that all textile products placed on the EU market are eco-designed, sustainable and with producers taking responsibility for their products along the value chain with sufficient capacities for recycling and ending incineration and landfilling.

To achieve this ambitious vision, Europe must unlock industrial-scale circularity for textiles. Design for disassembly is key to unleash the full potential of textile-to-textile reuse, repair, and recycling. Even with an ideal circularity infrastructure, most textile products on the market would remain too complex or expensive to repair or recycle once they become waste because they are not designed for disassembly and, therefore, circularity. Once collected, most cannot be processed without a pre-recycling step such as disassembly. This is a key end-of-life-problem for the industry. For example, over 78% of all textile products are multi-material and the presence of zippers and trims like elastic bands hinder recycling. This results in material loss as most textile waste goes to incineration or landfill, and most new textiles products manufactured from scratch.

Disassembly is still a manual and costly process. To address this, Resortecs’ active disassembly innovations – a range of heat-dissolvable threads (‘Smart Stitch™’) and thermal disassembly system (‘Smart Disassembly™’) – helps to replace textiles designed for waste with textiles eco-designed for disassembly, thereby enabling material recovery for reuse, repair, upcycling, and high-quality recycling as well as waste prevention. Active Disassembly represents the pinnacle of Design for Disassembly methodologies (other pre-recycling available today include mechanical disassembly and manual disassembly). By incorporating releasable fasteners in a product’s design and assembly – such as Resortecs’ SmartStitch™ – active disassembly delivers an automatic, non-destructive, and economic industrial disassembly process that segregates components and materials of a product at its end-of-life.

A major benefit of Resortecs is that it acts as a drop-in solution to the textiles value chain as no significant infrastructure or manufacturing changes are needed in the value-chain for implementation of this technology. It also delivers circularity without compromising the creativity, design, and quality of clothing.

Click here or on the image below to download the full position paper.

Resortecs’ feedback on the call for evidence on Textiles Labelling Regulation revision

Resortecs welcomes the European Commission’s initiative to revise the Textiles Labelling Regulation. In addition to delivering on the targets set in the EU Strategy for Sustainable and Circular Textiles and the EU Circular Economy Action Plan, this revision is an opportunity to:

(1) Integrate information and labelling requirements on disassembly, alongside those that will be set under the Ecodesign for Sustainable Products Regulation (ESPR) delegated act on textiles and for the EU digital product passport (DPP).

(2) Boost the sector’s circularity by building a standardised information infrastructure that encompasses cradle-to-cradle, expanding from today’s cradle-to-gate/grave information infrastructure.

Today, the textiles industry heavily relies on a linear model and does not design products for circularity. Only 1% of all garments are effectively recycled. A main barrier is the complexity of disassembling garments. To recycle a garment, it first needs to be disassembled – currently this is still a manual, labour-intensive, and costly process. This means that without efficient disassembly at scale, there will never be a truly circular textiles ecosystem.

Resortecs’s active disassembly innovation provides the solution to make recycling easy. Resortecs’ system of heat-dissolvable threads and thermal disassembly is five times faster than traditional disassembly and makes it possible to recycle up to 90% of a textile product’s fabric content. It is also a drop-in solution to existing industrial processes.

To make smart disassembly the norm, Resortecs urges the European Commission to:

1. Set information and labelling requirements covering disassembly, ensuring consistency with the ESPR and the DPP.

2. Build a standardised information infrastructure that expands from today’s cradle-to-gate/grave to cradle-to-cradle, including information on disassembly. Making this information available is essential to enable value-retention operations such as disassembly and high-quality recycling and to recognise product materials and components that enable ecodesign, such as Resortecs innovative threads for textiles. An ecodesigned product will only fulfil its circularity potential if the information needed – including crucial information on how it can be efficiently disassembled – is readily available and accessible to the right actor. Such a standardised information infrastructure is not available today, meaning that consumers, sorters, recyclers, and manufacturers lack crucial information throughout, from making informative purchasing decisions to processing a garment once it reaches its end of life. A garment’s physical label should contain simple, harmonised, and comparable visual symbols reflecting its key circularity characteristics. A garment’s readiness for disassembly should be included to guarantee adequate sorting, processing, and waste prevention, as well as a garment’s recycled and recyclable content. This information should also appear in a textiles product’s DPP and provide the detailed information substantiating the physical label.

3. An ambitious Textiles Labelling Regulation that goes beyond its current strict focus on fiber identification is crucial to spur circular innovation and foster the development of novel fibers. It should grant recognition to emerging innovative novel fibers and set a regulatory framework that allows them to scale.

On 7 September 2023, Creamoda, EURATEX, Fedustria, and Resortecs welcomed 150 changemakers from 20 countries in Brussels to discuss the future of the fashion and textile industries.

Resortecs unveiled its latest report, “From Waste to Profit”– A Comparative Cost Analysis of Textile Disassembly Processes, available for download here, and highlighted the financial and operational benefits of Active Disassembly compared to the status quo disassembly methods – manual and mechanical.

Dirk Vantyghem from Euratex gave an insightful update on the EU Textile Strategy launched last year with the aim to create a greener, more competitive textile sector. Textile products placed on the EU market need to be therefore more durable, repairable, recyclable, and to a great extent made of recycled fibers.

Textile recycling was highlighted as one of the solutions to drive change at scale and grow with environmental compliance, but getting there without losing the essential industrial competitiveness is of key importance for the sector.

The panel discussions with Fedustria and industry leaders Concordia Textiles, Sioen, and BekaertDeslee – moderated by Christine Goulay from Sustainabelle, resulted in a number of interesting insights and testimonials on the efficiency and applicability of Active Disassembly for the textile sector.

Carl Baekelandt, Demet Tunc, Ivan Deceuninck, and Karla Basselier shared their expertise as circularity pioneers. Here are three takeaways from the insightful discussions:

1. There are now 16 legal changes focusing on the sustainability and circularity of fashion and textile companies rolling out across the EU — and more will follow.

2. 78% of all textile products require disassembly before textile-to-textile recycling.

3. Europe is becoming increasingly dependent on recycling textile waste due to 1) the shortage of raw materials and 2) the prohibition of recycled R-PET from the packaging industry for use in other sectors.

In addition, all guests also had the chance to explore Circularium and witness a live demo of Smart Stitch™ & Smart Disassembly™.

The need of collaboration to unlock industrial-scale recycling in Europe was eminent at the networking dinner & drinks at the end of the event. The connections made are testament to the commitment of all stakeholders along the textile value chain to make circularity a reality.

Have you already downloaded your free copy of the report ‘From Waste to Profit’ — A Comparative Cost Analysis of Disassembly Processes? Download it here.

What’s inside?

• The best-performing disassembly method for achieving maximum financial and operational efficiency.

• How different disassembly methods compare across four textile product categories: multilayer outdoor jackets, cotton trousers, aramid-based workwear, and mattress covers.

• How fashion and textile brands can transform product recycling into a source of ROI rather than costs at the end of a product’s lifecycle.

• What policymakers and brands should do to keep the European textile and fashion industries competitive.

• Seed investment and EIC grant combined, the startup is tapping into €4.7M to boost production in 2023 and increase tenfold its disassembly capacity in 2024.

• Belgian Prime Minister, Alexander De Croo, highlighted the importance of funding circular entrepreneurship in a visit to the startup’s warehouse in Brussels.

BRUSSELS, BELGIUM – 26 April, 2023 – Belgian startup Resortecs has raised €2.2 million in a seed investment round led by Brussels-based ScaleFund and finance&invest.brussels. Founded in 2017, the fashion tech company develops design-for-disassembly technology to make textile recycling fast, easy, and cost-efficient.

makesense_invest, AFI Ventures (the impact arm of Ventech), Trividend, and PDS Limited also joined the funding round, which follows a €2.5 million grant received from the European Innovation Council (EIC) in 2022. In total, Resortecs is tapping into €4.7 million to boost production this year and finalize the development of a continuous disassembly line, scaling up tenfold its pre-recycling processing capacity to 10T/day in 2024.

Currently, less than 1% of fashion’s production is recycled, meaning a yearly loss of materials worth €500 billion and placing the sector in the world’s top 5 polluting industries. Behind these figures is the complexity of sorting recyclable and non-recyclable materials.

With Smart Stitch™ (heat-dissolvable thread) and Smart Disassembly™ (industrial-scale thermal disassembly system), Resortecs enables brands to make textile products designed to be easily sorted and disassembled for recycling. Bershka, Decathlon, and H&M already use Resortecs’ Smart Stitch™ heat-dissolvable threads in products sold in over 60 countries.

“Our goal is to reduce the textile industry’s carbon footprint by 40 billion tonnes of CO2 by 2040. For that, we have to think big and take design for disassembly beyond fashion. Our headcount has doubled in less than 6 months. In just a few weeks, Smart Stitch™ will also be found on the world’s first mattress covers designed for disassembly, made in collaboration with Belgian sleep industry leader BekaertDeslee.” – explains Cédric Vanhoeck, Resortecs’ co-founder and CEO.

The Belgian Prime Minister, Alexander De Croo, visited the startup’s warehouse in Brussels on 26 April and highlighted the importance of investing in Belgian circular entrepreneurship:

“As Europe does not have many natural resources, we have to make a choice: we can either look at everything we have already produced as waste, or consider it as potential future raw materials to protect the planet. Innovations like this are key to strengthening our industrial competitiveness. Resortecs is a fine example of green growth and Belgian innovation that is ready to take the world!”

By Rawaa Ammar, Impact & Sustainability Lead at Resortecs.

What do floods caused by extreme rain in Brazil, a heatwave hitting Antarctica, and heavy thunderstorms engulfing Brussels in May have in common? These are only but a subtle sign that climate change is an imminent threat, and that we need to act now.

Observing the water cycle and following how it evaporates into the atmosphere, condenses into rain, and flows back into the sea is an ideal example of how Nature is relying on circularity to sustain life on Earth. To understand such cycles, scientists have always relied on certain parameters throughout the different stages of their formation. The same concept is applied in Life Cycle Assessment studies (LCA), one of my go-to resources to measure impact as a Sustainability & Impact Lead at Resortecs.

An LCA is an environmental management tool that provides a better understanding of a product’s impact on the planet at each stage of its life cycle. It is a very strong tool that can be misused if misconducted. A recent Forbes article explains why environmental impact assessments could potentially undermine sustainable fashion. But does that mean we need to stop conducting LCAs to verify a product’s environmental footprint (PEF)? How will we get the information, and how can brands be held accountable for their sustainability claims?

LCAs should be especially important for the fashion sector, one of the top polluting industries, responsible for 1.2 billion tons of CO2 equivalent every year.

Two weeks ago, I had the opportunity to touch on this topic during a ChangeNow panel discussion on circularity in the fashion industry. The one thing we all agreed on is the critical need for more transparency and information on all things fashion. Data holds great power and framing scientific findings as an LCA can provide brands, legislators, investors, and end-consumers with vital information on the PEF of any product in our closet or shopping cart. LCAs should be especially important for the fashion sector, one of the top polluting industries, responsible for 1.2 billion tons of CO2 equivalent every year.

Concretely speaking, however, the question remains: what kind of change(s) must the fashion industry adopt to help keep the global temperature increase below 2°C, as set by the Paris Agreement? It is obvious that sustainability should be reinforced in every manufacturing aspect – from material sourcing to product design – but little is discussed spoken about the importance of true circularity and efficient waste management. Currently, 34M tons of garments are dumped by the global north in deserts, seas, and incineration yards all over the world every single year. This cannot go on. It’s time for brands to move from the “thinking about it” stage and start implementing, today, the best-performing technologies that can critically reduce and transform the waste of tomorrow.

At Resortecs, we’ve conducted an LCA to compare the impact of different textile disassembly solutions (manual, mechanical, and Resortecs) coupled with (mechanical, chemical, and Purfi) textile recycling. Using all possible combinations of disassembly & recycling processes, we calculated the difference between the PEF of a circular pair of jeans and the PEF of a benchmark pair that would end up incinerated or in a landfill.

The results are not at all shocking: recycling is one of the golden opportunities to transform the future of fashion… but if not done right or, even worse, if disassembly is not part of the equation, the entire effort to make the textile supply chain greener could be wasted. Compared to incineration, the right technical choice, like adopting Resortecs to automate disassembly and facilitate industrial-scale recycling, can reduce CO2 emissions by up to 50%. The impact doesn’t stop there:

• water consumption can be reduced by 98%;

• textile waste can be decreased by up to 80%;

• costs linked to toxicity remediation can be reduced by over 200 euros (per pair of jeans!).

By now, you are probably wondering if brands will need to spend more to pick these low-hanging fruits? While the short answer is yes (no innovation is cheaper than the status quo before it becomes mainstream), the right answer is no!

Shifting from linear production to a circular model, such as the one made possible by Resortecs’ Smart Stitch™️ & Smart Disassembly™️, is a medium-term investment that has many financial advantages for different players along the textile supply chain. To list only the benefits for brands, adopting Resortecs allows fashion giants to:

• reduce their carbon footprint and avoid offsetting costs or CO2 taxation;

• secure a continuous stream of traceable, recycled, sustainable materials;

• save up to 15% in production costs;

• get an ROI as high as 300% with payback within the year;

• and, ultimately, reduce the consequences of fashion production on climate change!

What do you think – can numbers and LCAs eventually stop the fashion industry from destroying the planet? Let me know in the comments sections.

If you are curious to discover how the fashion industry can reduce its annual emissions by 204 M tons in the coming 10 years, download our externally-reviewed Life Cycle Assessment.

Resortecs’ innovation – the first of its kind – can process up to 1 ton of garments per day and is being tested by 30 major global fashion brands

Recently, images of the mountains of unsold clothing dumped in the Atacama Desert, in Chile, shocked the world. Each year, 34 million tonnes of textiles worth more than 400 billion euros are wasted by the fashion industry – which became a strategic target of the EU Green Deal. Behind these alarming figures are the costs and complexity of disassembly and recycling. When faced with stacks of unsold inventory, that might reach up to 40% of each season’s production, fashion brands turn to options easier and cheaper than recycling, such as landfills or incineration. If it’s up to Resortecs, however, this scenario is about to change.

The start-up presents its first thermal disassembly system in a demonstration event for the press, politicians, investors, and industry peers in Brussels on Thursday, 09/12. The system combines heat and mechanical force to disassemble clothes stitched with Resortecs’ heat-dissolvable threads. Inside the system – a globally-patented, high-tech version of an industrial oven – the clothes are exposed to specific temperatures, making the seams disappear automatically and allowing for easy material sorting and recycling.

“The system works with little to no oxygen inside. This preserves the fabrics’ quality and prevents the clothes from burning, even when they are submitted to temperatures higher than 200° C”, explains William Allouche, Technical Lead for Disassembly and the mind behind the system’s engineering. “We’ve made sure to develop a closed-loop system to preserve the heat produced for each batch of clothes for the longest time possible. This ensures energy recovery and generates way less CO2 emissions than other heat-induced processes.”

The thermal process is 5x faster than traditional disassembly methods and enables the recycling of up to 90% of the original fabric material, instead of the usual 48% obtained after manual or mechanical disassembly. Using data to prove the impact of its innovation, Resortecs ran an externally-reviewed life-cycle assessment which shows that the process adoption could help the fashion industry cut its CO2 emissions by 50% and reduce waste generation by 80%. If the entire EU production were thermally disassembled and recycled, the fashion industry could generate 60.3 million fewer tons of CO2 and save up to € 2.3 billion per year.

The version presented to the public is just a prototype. It can process up to 1 ton of textile per day and is being used to show first partners, such as the fast-fashion giant H&M and other 30 global fashion brands, how the start-up’s solution works. In the long term, it will be part of a network of thermal disassembly systems placed in recycling plants all over the world. The idea is to cover the globe with automatic thermal disassembly to speed up global textile recycling. Still in 2022, a second system with a larger processing capacity will come into operation. Together, both units will be able to prepare up to 13 tonnes/day of clothing for recycling, an unprecedented volume in the world.

“Everyone thinks of recycling, but no one looks at the biggest challenge to make it happen: disassembly. We saw an opportunity to optimize production while boosting up recyclability and sustainability, and we jumped on it” says founder Cédric Vanhoeck. “Brands have finally realized that there’s no way to continue producing and wasting textile as if nothing is happening with the planet. When we started 4 years ago, brands complained about the costs of sustainability, now they come to us because they understand that circularity is an investment.”

Join us.

Subscribe to our newsletter.

By subscribing, I agree with having my personal data stored and processed by Resortecs so I can receive future updates and marketing offers.